Cosworth DFV V8 Formula 1 History

Cosworth F1 Engine: The Story

The most successful F1 engine in history

Ford Cosworth engined cars won 176 GPs, many of them with the legendary Cosworth DFV engine, which dominated F1 racing for a long time. 12 Of the 15 drivers and 10 constructor world championship titles between 1968 and 1982 were won by drivers with Ford Cosworth engines, 131 pole positions. Plus wins at LeMans and at Indy with the DFX version. In North America the DFX and XB engines dominated the CART and Indy formula leading to Cosworth receiving the Queen's Award for 'export achievement' in both 1986 and 1992. In this time more than 500 units were produced. The only other engine with more than 100 GP wins is Ferrari (236), Mercedes (173), and Renault closing in currently with 168 wins.

Keith Duckworth and Mike Costin

Founders of Cosworth

Keith Duckworth and Mike Costin founded the company Cosworth in 1958 in a little shop with just the basics, like an engine stand, in Shaftsbury Mews, London, England. The two Englishmen wrote their own success story for over 20 years before Cosworth was sold for the first time in 1980 to United Engineering Industries. However, both continued to be involved in the firm even when it changed hands again later in 1990. After Duckworth's retirement, the Vickers Group took over the ownership

and then, in 1998, sold Cosworth Engineering to the Audi Group, with a potentially dramatic effect on Ford's racing program. Until 1998 the company was split in two: Cosworth Technology (including the engineering, manufacturing and casting units) stayed with the Audi Group, while Ford Motor Company took control of Cosworth Racing and the company became a works engine and electronics supplier to the Stewart Grand Prix Formula One team and its successor - Jaguar Racing.

Finally, Mahle Group, one of the leading independent engine specialists, with over $4 billion in annual revenue, acquired Cosworth Technology from Audi, and renamed it to Mahle Powertrain.

In 2004, Cosworth was purchased by Jerry Forsythe and Kevin Kalkhoven, co-owners of the Champ Car World Series (the successor to CART).

Duckworth and Costin made the pages of motor sports history in openwheel, rally and closedwheel racing over the years. Their accomplishment in Formula One tops the charts.

The first assignment that the two new partners accepted after the founding of the new company was to develop parts for the Ford road car engines, concentrating on the Mk1 - a modified 4-cylinder pushrod Ford 105E Anglia engine.

Cosworth has had a long and distinguished career in Formula One, beginning in 1963. The 3.0 ltr V8 DFV engine won everything going in F1 for years (154 victories over the various generations of the engine) and some would say the ‘new’ V8's in F1 owe a lot to it’s existence.

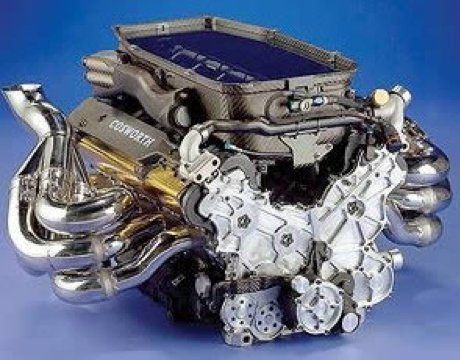

In 1966, Duckworth designed the DFV (Double Four-Valve) F1 engine on behalf of Ford Motor Company, at the time, he simply stated, "We are too small as a company to allow development and debugging to win over sound design." Named Four Valve because of the four valves per cylinder, and Double as it was a V8 development of the earlier, four-cylinder FVA (four valve type A engine of 1600cc), making it a Double Four Valve engine.

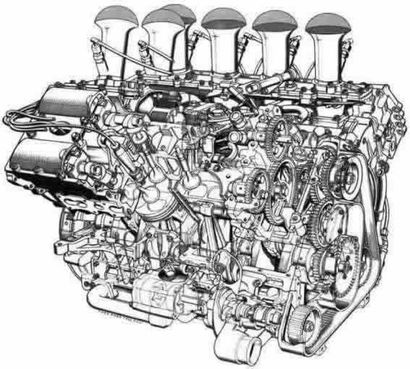

The engine was a 90°, 2,993 cc V8, with bore x stroke of 85.67 x 64.897 mm producing over 400 bhp (408 bhp at 9,000 rpm, with (370 N·m) torque at 7,000 rpm) from the start, reaching 510 bhp at 11,200 rpm by the end of its Formula 1 career. The DFV had three major upgrades over its life in the top formula, with the development of first the DFY and then the DFZ, followed by a major redesign to produce the final DFR type. DFV engine featured 32 valves operated by twin overhead camshafts driven by a train of 9 gears. The metering unit for the Lucas mechanical fuel injection was rotated by gear and belt from the inlet cam, while the exhaust cam drove an alternator on the rear of the head. This engine dominated Formula 1 until 1971, and was also used in sports car racing in 1.8 litre form as the FVC. The FVA was notable for being part of the same Ford contract that gave rise to the DFV; the cylinder head on the FVA pioneered many of Duckworth's ideas that would be used on the V8 engine.

Walter Hayes, the public affairs director at Ford, in turn, offered the engine to Lotus, which had been stranded without competitive engine following the withdrawal of Coventry Climax after FIA changed to the three-litre formula for the 1966 season. That three-litre V8 engine, which debuted in 1967, turned out to become the most successful Formula One engine of all time, winning their first race out of the box.

The DFV won on its first outing, at the 1967 Dutch Grand Prix in the hands of Jim Clark, fitted to a Lotus 49, and from 1968 was available for purchase to any F1 team that wished it. During the 1970s, it was common for almost the entire field (with the notable exception of Ferrari) to use one of these engines - this at a time when independent wealthy individuals could buy exactly the same engine off the shelf that was also being used by McLarenl. Most teams just built a tub around a Cosworth DFV and a Hewland gearbox. It won a record 155 World Championship races, the last being Detroit in 1983, powering a Tyrrell driven by Michele Alboreto.

Running on "pump" gasoline, 1967's Cosworth DFV produced 133hp per liter. Astonishingly, the last Cosworth 3.0-liter, Formula 1 engine, fed comparable fuel and likewise naturally aspirated, produces about twice that! DFV of 1967 set the pattern for the contemporary engine with its "supersquare" (wider than higher) cylinder dimensions, its pent-roof shape combustion chamber, its narrow included valve angle, its four valves per cylinder operated by double overhead camshafts and its clean porting. The DFV was not radically different from previous engines, Its significance was that its detail design took advantage of the potential of four, rather than two valves per cylinder for enhanced breathing and burning - the fundamentals of effective combustion. Although the DFV did not produce as much power as some of its rival 12-cylinder engines, it was lighter, resulting in a better power to weight ratio. In addition to being lighter, it was also made a structural part of the car itself, by placing load bearing arms to stress the block. These design aspects appealed tremendously to the genius of Colin Chapman who used them to the fullest extent.

The power output of the four-stroke internal combustion engine is a function of the torque seen at its flywheel and the speed at which that flywheel spins. Power per liter per 1000rpm as measured on the dyno is the so-called brake mean effective pressure (bmep) that indicates torque. The Vanwall of 1957 produced its 120hp per liter at 7300rpm, at that engine speed giving 16.44hp per liter per 1000rpm-a nitro- boostedpeak power bmep reading of 14.7 bar. The DFV of 1967 produced its 133hp per liter at 8500rpm- 15.65hp per liter per 1000rpm, a peak power bmep reading of 14.0 bar. This fall in specific torque recognizes the far less potent fuel used in the DFV.

The increase in performance of the 3.0-liter engines is purely a function of faster flywheel (crankshaft) speed. To attain 800hp, a current F1 engine must turn in the region of 17-18,000rpm, which means its peak power bmep roughly equals that of the 1967 DFV. In fact, as crankshaft speed rises, the tendency is for bmep to fall - the combustion event has to take place in a correspondingly shorter time and frictional and other losses increase disproportionately. On the other side of the coin, the fact that the current F1 engine can match the peak power bmep of the DFV of 1967 running at half its speed is a tribute to considerable development devoted to overcoming the inevitable losses that occur with rising speed. It should be noted that some internal losses quadruple with the doubling of running speed. Measures to counteract these losses include a drastic reduction in bearing sizes, the development of high-performance coatings for the bearings, the piston and liner and so forth, and a conceptual revision of the oiling system.

The 32-valve DFV V8 had an 85-67mm bore, while today's V8s have bore sizes in the region of 98mm maximum, with correspondingly larger valves (albeit aluminium alloys rather than the steel employed in 1967).

A key feature of 1967's DFV was its packaging. Very compact by the standard of this days. Significant benefit for the chassis designer, but compared to a current V10, it looks huge. Today's clutch is much smaller in diameter (115mm. now vs. 200mm then), the crankshaft is set significantly lower and the whole package is more tightly knit. While the cylinder count is the ultimate constraint, with some lateral thinking last season Cosworth reduced the size and weight of its engine by dispensing with traditional wet liners.

Another major development since '67 has been the advent of engine management systems. Contrary to popular belief, the precision of computer-timed ignition and fuel injection does not automatically increase maximum power, at least in the case of a pure race engine, but it does help keep everything running on cue as crankshaft speed rises.

More than 150 GP wins came on the engine that Duckworth designed, as the Ford Lotus team dominated F1 with his original design -- and a few modifications for increased power output and FIA rule changes. This feat has yet to be equaled in the racing world. Until, that is, the rise of the turbocharged engines and the end to the decade-long domination by Cosworth, Ford and Lotus.

"Turbochargers were for people who can't build engines," was a quote attributed to a frustrated Duckworth in the early 1980s.

Cosworth later built the DFZ and HBA 3.5L normally aspirated F1 engines for Ford, and supplied electronics to a wide variety of F1 engines. The company continues its involvement, and after 2 years out of Formula 1, they supply CA2010 V8 engines to AT&T Williams, LotusF1 Racing (later Caterham F1), Virgin Racing (now Marusia), HRT F1 during season 2010.

2006. Cosworth CA was the first Formula One engine to reach 20,000 rpm on track. From 1906 through to 2006, Grand Prix engine speeds rose ever higher, from less than 2000 rpm to ultimately a mind-boggling 20,000 rpm. Then the rule-maker abruptly halted the march of progress with a 19,000 rpm rev limit for 2007, subsequently reduced to the current 18,000. It is generally agreed that no rival surpassed it as the benchmark before rev limiting was imposed.

It is widely agreed that BMW reached 19,000 rpm first, in 2002. However, engine mileage requirements were lengthened in 2004 and 2005, which had the effect of pegging the ongoing crankshaft speed rise. Representative of the top 2005 V10s was the Toyota that ran to a maximum of 19,200 rpm and produced an estimated 930 bhp mid-season. All of the 2005 V10s exceeded 900 bhp but it is not thought that any exceeded 950 bhp, with the possible exception of the Honda at the end of the season.

Cosworth's 2005 V10 was the TJ model, which had its max RPM at 19,000 rpm. With next year model CA, Cosworth took the uncompromising approach of targeting 20,000 rpm from the outset. This was the first time it had produced such a high-speed V8. At 20,000 rpm the CA's maximum piston acceleration was 10,616 g while the load imparted on each crankpin by the associated piston and con rod reached a very substantial 5937 kg at that unprecedented speed. To put that into context, an anti-ballistic missile attains a g-force of only 100 g while 5937 kg is approximately two and a half times the weight of a Rolls Royce Wraith!

During 2012, Cosworth continued to supply Marussia and HRT on the F1 grid and is working on a 2014 powertrain when the sport will switch to V6 turbos.

On October 18, 2012 news broke out that Cosworth Group has been put up for sale after abandoning plans to float on the stock exchange. The Times reports that aircraft engine company Rolls-Royce and other aerospace companies are likely to be interested in buying the company after it has diversified in recent years.

Cosworth made an attempt at designing a full Formula One Grand Prix car in 1969. The car, designed by Robin Herd, used an original 4WD transmission designed by Keith Duckworth (different from the Ferguson used by all other 4WD F1 cars of the 1960s) and powered by a magnesium version of the DFV unit. Duckworth himself developed this special 4WD DFV engine that was totally cast in magnesium, and a proprietary Cosworth gearbox containing Hewland gears, different from the Ferguson used by all other 4WD F1 cars of the 1960s.

As with every 4WD car the engine was turned 180 degrees with the clutch facing forward. From there the gearbox stepped down power by way of several gears to an angled central differential on the right hand side of the cockpit - creating a slightly off-set driving position. From the centre differential fore and aft shafts ran across the entire length of the wheelbase. The rearward shaft went to the back of the engine where a transfer box took power back to a centrally-positioned rear diff. By using the driveshaft inboard disc brakes could be employed at the front and the rear.

Same year Cosworth tested their 4WD car. It proved uneasy in roadholding with strong understeer and most weight moving to the outside wheel during cornering even lifting the inside wheel at times. Also excess understeer caused by the heavy front differential. They even persuaded Jackie Stewart to slip into the car for a few laps, who reported back that, "It's so heavy on the front, you turn into a corner and the whole thing starts driving you. The car tries to take you over."

The car was planned to drive at the 1969 British Grand Prix, they entered the car for Trevor Taylor to drive, but it was silently withdrawn.

When Herd left to form March Engineering, the project was cancelled. The external design of the car was a product of Herd's use of Mallite sheeting (a wood-aluminium laminate composite) for the principal structural monocoque sections, a technique he pioneered on the first McLaren single-seat cars, including the McLaren M2B of 1966.

155

Grand Prix wins

10

Constructor world championships

131

Pole positions

500+

Produced engines